Emergency generators provide electrical energy and differ in terms of their drive and functionality. In this article we would like to explain which emergency power generators there are and how they work.

An emergency power generator (also called emergency power generator or emergency power system) is a machine for generating electricity that is used if the regular power supply fails.

Emergency generator function

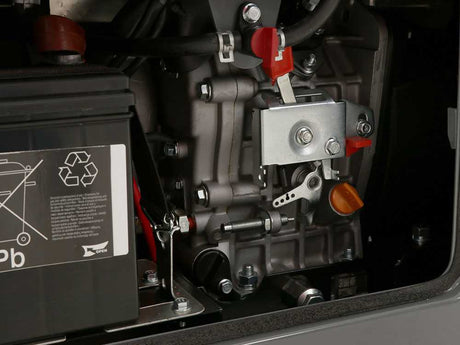

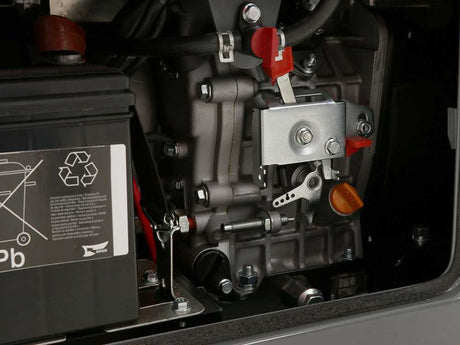

The function of emergency power systems is quite simple, because a conventional emergency power generator consists of only two basic components: an internal combustion engine (drive) and a generator (energy producer). While the engine drives the generator, it generates a voltage that is delivered to the consumers.

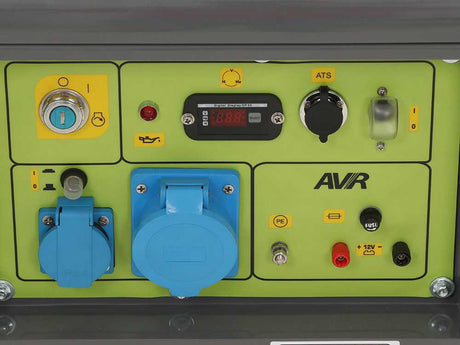

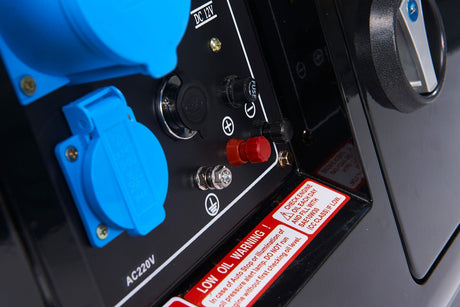

There are also other unit parts such as the fuel tank, the control of the engine speed and generator voltage, monitoring sensors (lack of oil, overload), safety devices such as insulation monitoring or FI circuit breakers, as well as a terminal strip or socket panel and possibly sound insulation.

Regardless of whether an emergency power system is operated with diesel or gas - in emergency situations such as a power outage, the emergency generator should generate electricity for as long as possible. The expected running time and the amount of energy required are therefore crucial when sizing the tank. Small, compact models usually have a smaller tank than larger emergency generators. Some units also consume more fuel than others.

Types of emergency power systems

The most common emergency power systems are the following:

Emergency generator with combustion engine (diesel, gasoline and LPG): The liquid fuel is stored in a tank of the device and is therefore reliably available to the generator.

Gas emergency power generator: In large systems, gas turbines are often used to drive the generators.

PTO generator as an emergency generator: A PTO generator does not have its own combustion engine, but rather uses the engine of a tractor or other vehicle with a PTO connection. The speed of the PTO shaft is transmitted via a gearbox to the generator, which runs at 1500 rpm and generates 400V three-phase current. For use as an emergency power feed, the PTO generator needs to be switched over to the TN network. Electricity is often transmitted into the building using a 1-hour high-voltage socket.

The advantage of these emergency power devices is that the maintenance-intensive part of the system - i.e. the combustion engine - is no longer necessary. This means that the purchase costs are lower than for power generators with a motor of the same size and most maintenance costs are eliminated during the period of use.

Battery-operated emergency power supply: Smaller, rechargeable batteries or accumulators are often used in conjunction with an inverter. The batteries are charged via the regular power supply and can ensure the energy supply without interruption (UPS = uninterruptible power supply). Since these devices have comparatively small batteries, they can only provide power for a short period of time and for selected consumers.

Combinations of batteries and combustion engines: This solution is being chosen more and more often because it offers several advantages. The batteries support the power generator at high loads, load peaks, but also at low loads (below 30%), so that the power generator can run in an optimal operating state. Load peaks are absorbed by the batteries, so that a smaller power generator can often be chosen. When the load is low, the power generator can remain switched off and the batteries supply the electrical consumers.

Emergency generator with inverter: With an emergency generator with inverter technology, the combustion engine can run at a different speed than would be necessary for the mains frequency of 50 Hz. This is possible because the combustion engine and generator first generate direct current and this is then converted into 230V alternating current at 50 Hz by the inverter. The emergency power generator therefore has the option of adapting the engine speed to the amount of energy required (in partial load operation). The results are very quiet inverter generators and lower fuel consumption. If you want to be independent when it comes to power supply and are looking for an emergency generator for your home, you can purchase these small emergency generators. An emergency generator for a single-family home generates electricity for your own needs and can also be taken camping or to the allotment garden.

Emergency generator with hydrogen fuel cell: Here, hydrogen is used as an energy source that reacts in the fuel cell and thus releases electrical energy. The function of the fuel cell can be compared to that of a battery. As electrochemical cells, both have an anode and a cathode, but are powered by different fuels. Fuel cell technology relies on hydrogen, which is not stored in the unit like a battery, but rather reaches the anode from a tank. To generate electricity, hydrogen fuel cells require oxygen, which is supplied to the cathode. The hydrogen reacts with oxygen to form water.

The biggest advantage of fuel cell technology compared to combustion engines is its environmental friendliness. The hydrogen fuel cell does not produce any harmful exhaust gases such as nitrogen oxides or carbon monoxide, but only waste heat and water vapor. The fuel cell also works much more quietly than conventional combustion units.